Proper maintenance on your Auxiliary Power Unit (APU) increases your fuel economy, lowers engine wear, increases driver comfort, reduces engine idle time and increases the trucks value.

Idle Time and Semi-Truck Engines: Understanding the Impact

Idle time, defined as the duration when a semi-truck engine is running but stationary, poses various challenges to engine health and overall performance. In this discussion, we’ll delve into the consequences of prolonged idling on critical engine components, fuel efficiency, emissions, and explore strategies to mitigate these effects.

Increased Wear and Tear

Extended idling takes a toll on vital engine components such as pistons and bearings, potentially diminishing the engine’s longevity. The continuous operation without the benefits of motion contributes to heightened wear and tear, necessitating increased maintenance. Installing or using an APU to reduce idle time will save on excessive engine wear.

Reduced Fuel Efficiency

One of the most notable consequences of idling is reduced fuel efficiency. As the engine runs without contributing to forward motion, fuel is consumed without generating mileage. This has a direct impact on operational costs, making it crucial for truck operators to address excessive idling. APU’s use much less fuel to power accessories and the heating and cooling of your cab.

Oil Contamination and Degradation

Incomplete combustion during idling can result in the accumulation of contaminants in the engine oil. This compromises the lubricating properties of the oil, leading to accelerated oil degradation and increased wear on engine components. Auxiliary Power Units help save you on oil changes as less deposits build up in the engine from idle time.

Cooling System Inefficiency

During idling, the cooling system’s effectiveness is compromised as there is limited airflow. This can result in elevated engine temperatures and potential overheating issues, emphasizing the importance of proper cooling system maintenance.

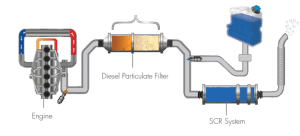

Challenges with Emission Control Systems

Trucks equipped with emission control systems, such as diesel particulate filters (DPF), may face challenges with incomplete regeneration during prolonged idling. This not only impacts overall engine performance but also raises concerns about emissions compliance. Idle time is one of the main killers of DPF and emissions components. APU’s allow the main engine to be shutdown and the result is no excessive emissions and less particulate matters building up in the DPF and less REGENS! Less regens mean less fuel use.

Electrical System Strain

Continuous idling places strain on the electrical system, affecting components such as the battery and alternator. Over time, this strain can lead to increased wear on these essential components, potentially resulting in starting issues. Newer Auxiliary Power Unit systems can be programmed to automatically startup and charge the vehicle’s main batteries when they drop below a certain voltage. Thus, saving on battery life.

Environmental and Regulatory Considerations

Excessive idling contributes to unnecessary emissions of pollutants, impacting air quality and the environment. Moreover, it may lead to non-compliance with anti-idling regulations in certain regions, attracting fines and penalties for trucking companies. APU’s help lower your carbon footprint while also lowering your overall fuel bill and increasing your MPG.

Mitigating the Impact of Idle Time With a Auxiliary Power Unit

To address the negative effects of idle time, truck operators should consider implementing strategies such as advanced idle reduction technologies, establishing anti-idling policies, and optimizing trip planning to minimize unnecessary engine idling. Additionally, regular maintenance practices, including timely inspections and adherence to service intervals, play a crucial role in maintaining engine health despite the challenges associated with idling. By adopting these strategies, trucking companies can enhance operational efficiency, reduce costs, and contribute to a more sustainable and environmentally friendly transportation industry.

A Guide to Proper Maintenance of Auxiliary Power Units on Semi Trucks

In the world of long-haul trucking, reliability is key. Truckers spend countless hours on the road, and having a dependable Auxiliary Power Unit (APU) is crucial for comfort, efficiency, and reducing fuel consumption. In this article, we will delve into the importance of maintaining your semi truck’s APU and provide a comprehensive guide to proper maintenance practices.

Understanding the Auxiliary Power Unit (APU)

An Auxiliary Power Unit is a small engine integrated into a semi truck to provide power for various onboard systems when the main engine is turned off. APUs are commonly used to run heating, air conditioning, and electronic devices, allowing drivers to rest comfortably during breaks without idling the main engine.

Why Proper APU Maintenance Matters

- Extended Lifespan: Regular maintenance ensures that the APU operates efficiently and has a longer lifespan. This, in turn, helps truckers avoid costly repairs or premature replacements.

- Fuel Efficiency: A well-maintained APU consumes less fuel than a neglected one. This is crucial for reducing overall fuel costs and minimizing environmental impact.

- Reduced Downtime: Unexpected breakdowns can result in significant downtime for truckers. Regular maintenance helps identify potential issues early on, preventing unexpected breakdowns and keeping the truck on the road.

- Compliance with Regulations: Adhering to maintenance schedules ensures compliance with environmental regulations that restrict idling, contributing to a cleaner and greener transport industry.

Maintenance Tips for Your APU

- Regular Auxiliary Power Unit Inspections: Conduct routine visual inspections to check for loose connections, leaks, or any signs of wear. This should include examining the Auxiliary Power Unit unit itself, as well as associated components like hoses and electrical connections.

- Fluid Checks and Changes: Regularly check and change the oil and coolant as recommended by the manufacturer. Clean fluids contribute to optimal APU performance and prevent unnecessary wear and tear.

- Air Filter Replacement: Replace air filters according to the manufacturer’s guidelines. Clean air filters ensure proper airflow to the APU, maintaining efficiency and preventing engine damage.

- Battery Maintenance: Check the APU battery regularly for corrosion and ensure it is securely connected. Weak or faulty batteries can lead to startup issues and reduced APU performance.

- Exhaust System Inspection: Inspect the exhaust system for leaks, rust, or damage. A well-maintained exhaust system ensures that the APU operates cleanly and efficiently.

- Software Updates: Keep the APU software up to date by installing recommended updates. This helps optimize performance and may include improvements or fixes to potential issues.

- Professional Servicing: Schedule regular professional servicing to address more complex issues and ensure that the APU receives a thorough inspection from experienced technicians.

Why It Is Crucial to Maintain Your Auxiliary Power Unit

Maintaining your semi truck’s Auxiliary Power Unit is not just about ensuring comfort on the road – it’s a crucial aspect of responsible and cost-effective trucking. By following a comprehensive maintenance routine, truckers can enjoy a more reliable APU, reduce fuel consumption, and contribute to a sustainable and efficient transportation industry. Remember, a well-maintained APU is not just an investment in your truck; it’s an investment in the success of your journey on the open road.

Inspecting your Auxillary Power Unit System is one of the many checkpoints of our Pre-Purchase Inspections. We include oil sampling analysis with every truck that is equipped with an APU so you can see the internal wear. We also run each APU during our inspection and ensure it powers the proper equipment as required. For more information about a pre-purchase commercial truck inspection please fill out the form on this page or send us a message here.